Improving Industrial Accuracy: X-Y Rail Systems in Steel and Aluminum

Introduction: -

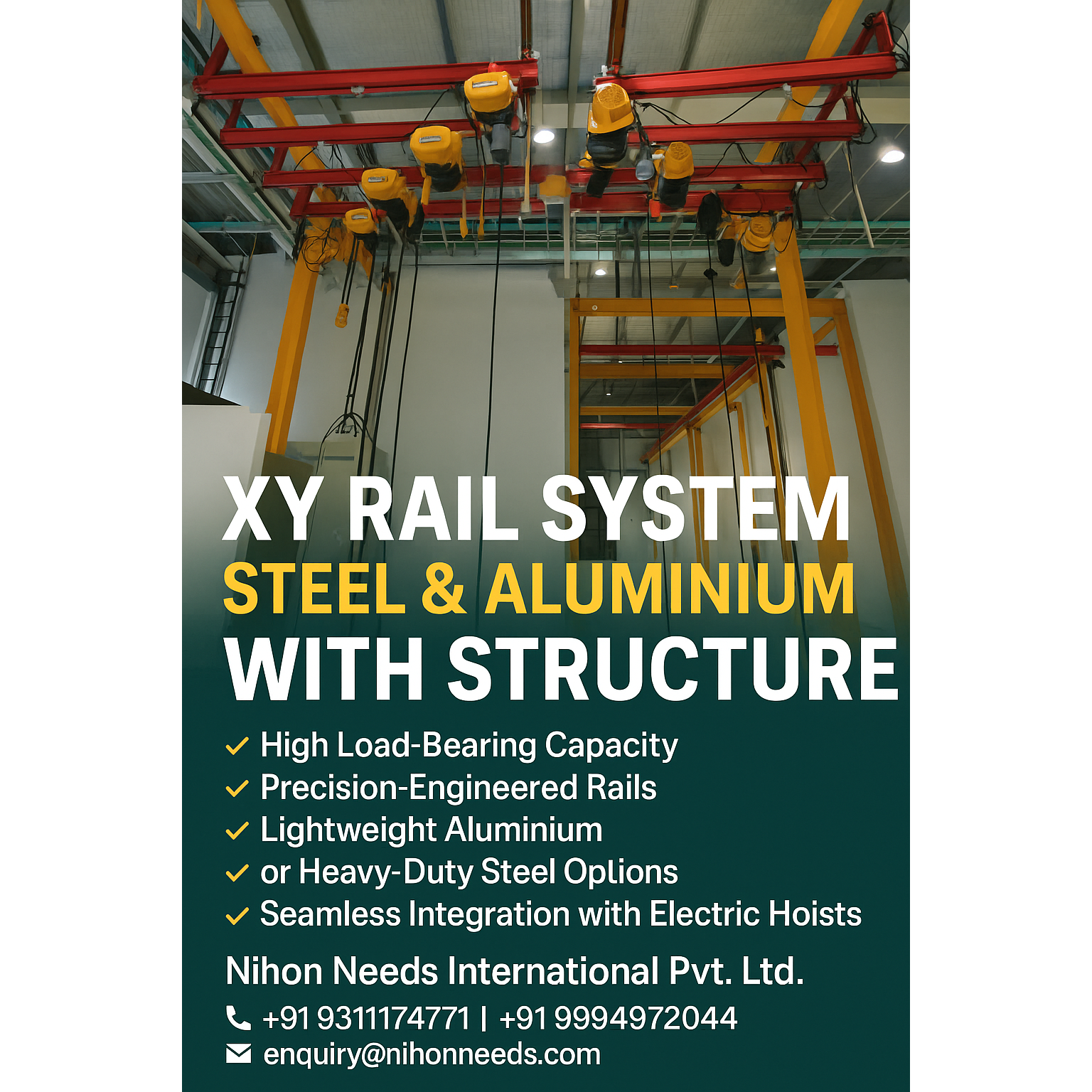

Precision, longevity, and versatility are the key in today's industrial environments. An important element that upholds these principles is the X-Y rail system—a mechanical device through which movement on two axes is enabled. From CNC equipment, automated inspection systems, to robotics, selecting the appropriate rail system has a direct impact on efficiency in operations. Herein, we discuss the advantages, usage, and structural aspects of steel and aluminum X-Y rail systems for industrial applications.

What Is an X-Y Rail System?

An X-Y rail system consists of linear guide rails and bearings that provide motion in the X and Y directions. These systems are critical for tasks involving multidirectional movement, high-precision positioning, and repeatable operations. They serve as the basis of many applications such as:

1- CNC machines

2- Automated assembly lines

3- Packaging systems

4- Laser cutters and engravers

5- Industrial 3D printers

Material Matters: Steel vs. Aluminum

When choosing or specifying an X-Y rail system, the material is paramount to performance, longevity, and cost.

A- Steel X-Y Rail Systems

Benefits:

1- High Strength & Load Capacity: Suitable for heavy-duty usage.

2- Exemplary Wear Resistance: Resists high-cycle operations for extended periods.

3- Minimum Deflection: Retains precision even with high mechanical loads.

Best Uses:

1- Automotive manufacturing

2- Aerospace part machining

3- Large-scale CNC milling

B- Aluminum X-Y Rail Systems

Benefits:

1- Lightweight: Lower transport, installation, and integration costs.

2- Corrosion Resistance: Ideal for environments where chemicals or moisture are found.

3- Lower Inertia: Allows for acceleration and movement at a faster rate.

Ideal Applications:

1- Electronics assembly

2- Light-duty material handling

3- Medical device manufacturing

Structural Integration & Design Considerations

A successful X-Y rail system is not simply about rails and bearings—structural integration plays a crucial role. The structure that attaches to the rails needs to provide alignment, reduce vibration, and sustain static as well as dynamic loads. Some structural considerations are:

1- Use of Base Frames: Steel or extruded aluminum base frames provide increased rigidity.

2- Cross-Bracing: Provides added structural stability for taller or wider systems.

3- Modular Design: Facilitates simple customization or expansion in future upgrades.

4- Regardless of whether you are integrating rails into an existing structure or creating a system from the ground up, alignment and load distribution are key to maintaining high accuracy and long life.

Selecting the Proper System for Your Application

When choosing an X-Y rail system for your production process, consider the following:

1- Load specifications (static and dynamic)

2- Environmental conditions (humidity, dust, chemicals)

3- Precision and velocity requirements

4- Space available and mounting arrangement

5- Budget limitations

Several manufacturers have pre-assembled X-Y stages available, but in the case of custom projects, collaborating with a qualified supplier to create a customized system is usually the most suitable option.

Conclusion

The selection of a steel or aluminum X-Y rail system is a function of your application's unique requirements. Steel provides unparalleled strength and longevity for heavy-duty applications, while aluminum offers light weight with versatility and corrosion resistance. By thinking in terms of both the material and the support structure, you can construct a system that increases productivity, provides longevity, and achieves your industrial performance objectives.

Need assistance with selecting or designing an appropriate X-Y rail system for your use?

Call us now for professional consultation and custom engineering services.

XYRailSystem

OverheadCrane

AluminiumRails

SteelStructure

MaterialHandling

CraneSystems

ElectricHoist

FactoryAutomation

RailSystemIndia

ManufacturingSolutions

IndustrialAutomation

EngineeringTools

FactorySetup

SmartManufacturing

HeavyLifting

IndustrialCranes

WarehouseTech

ProductionLine

NihonNeeds

MadeForIndustry

BuiltToLift

EngineeringIndia

B2BTech

ToolTech

WorkshopUpgrade

InnovationInMotion

PowerToMove

MadeInJapan

DistributedInIndia

Keywords

repeatable operations

support structure

heavyduty applications

existing structure

integrating rails

performance longevity

professional consultation

increases productivity

corrosion resistance

unparalleled strength

qualified supplier

production process

load distribution

future upgrades 4

sustain static

crucial role

provide motion

advantages usage

direct impact

robotics selecting

important element

customized system

proper system

industrial applications

structural considerations

structural aspects

dynamic loads

rail system

base frames steel

todays industrial environments

linear guide rails

long life selecting

xy rail system

industrial performance objectives

added structural stability

high mechanical loads

suitable option conclusion

custom projects collaborating

preassembled xy stages

maintaining high accuracy

bearingsstructural integration plays